219

3826

Taking Time: Finishing at Greubel-Forsey.

Over coffee one morning, while talking with Robert Greubel, I asked him where he saw the future of Greubel Forsey. After all, in the space of five years, the firm had essentially grown from two watchmakers into a firm with about 63 employees. Greubel Forsey has just moved into their new premises on the outskirts of Chaux de Fonds, and it seemed the moment to ask. Robert’s concern was that the future for Greubel Forsey would be the same, even if far into the future, the two founding men were no longer there, that the philosophies that had started the two watchmakers out to set up their own firm would continue. That the watchmaking, dedicated to innovation and experimental testing, would be there producing inventions that had tangible and known improvements in the performance of the mechanical watch.

It was with a vision for the future that Robert and Stephen took on finding a home for the disparate set of workshops and offices that had been built up around the former horse stables at Chaux de Fonds. While Robert and Stephen realized that a new building was required, they had to find the site. The site they ended up with already had an old farmhouse on it, in a dilapidated state, and with permission to level the old building and start to build again. Rather than destroy the old, a new plan evolved: keep the farmhouse, renovate it, and include it in the new building for the manufacture. And here, even in the design of their purpose built manufacture in the Swiss mountains outside of Neuchatel, Robert and Stephen’s philosophy pervades the building itself.

As you approach the building from the front, the old farmhouse (the entrance to the reception area) lies to the right; the remainder of the building to the left. Within the old farmhouse are the corporate meeting room, Stephen’s office, and administrative offices; Robert maintains his office as before in Lignieres. All aspects of the old house have been preserved, or replaced to the original. The old cellar, a period old oven and tiled stove heater, window sills, floors, roof rafters, stone work were all preserved. The left-hand side of the farmhouse was then removed from the basement up to the roof to accommodate the link to the modern building.

The modern part of the structure took some inspirations of the old stable house in Chaux de Fonds and moved it into the modern age. There is a central atrium that is now part of the building with the various parts of the manufacture running off either side. The building is filled with natural light, but in the same way that the light can be adjusted depending on the apex of the sun, the light and the windows can also be used as a means for controlling heat in the building. The glass on the side of the building is double skinned, creating a buffer zone with circulating air in summer and tapped air to heat in winter (keeps the cold out, but then the building also heats up like a greenhouse). The glass is therefore movable and the heat can be adjusted using the degree to which the cold air filters in and the heated air escapes out the vent.

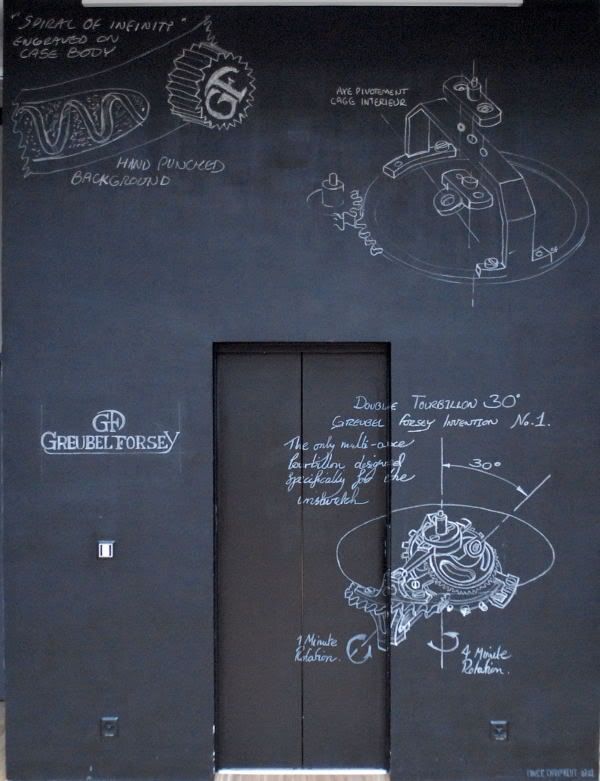

The building to the outside may look ordinary enough, but the beauty is accentuated in the details. From the central elevator with the ‘chalked’ drawings from the beautifully inlaid wood flooring, down to even the original sun-dial on a window sill on the south side of the old farm house. The sundial still tells the time (although Stephen reckoned that it was GMT as when using the pen as an indicator, the time was one hour behind the time on our watch!). It is more than just finishing for finishing sake. It is reflection of philosophy and belief in how even in the smallest detail, it plays a part, even it not actively seen, and that it should receive the same care and attention as parts that are visible, from distance, or close up.

Greubel Forsey watches are paragons of finish and attention to detail. While Robert and Stephen have earned their well deserved reputation through innovation and inventive watches, it is how the inventions are presented, how the piece is executed, that differentiates the watches handcrafted at Greubel Forsey’s new atelier in Chaux de Fonds.

The difference between ordinary goods and luxury goods is something intrinsic in the nature of that production. The small touches that differentiate that reflect that this was the product of a skill and dexterity possessed by an individual rather than a machine. At first glance it is the simplest of things that might differentiate the hand made/hand finished from the machine made/machine finished. While the need for hand finishing might be obviscated from view, it adds to the quality and construction of the watch. Parts that are hand finished match together in a more esthetic form, the less wear and tear on the moving parts, and the bridges and plates align and fit in a more harmonious manner.

When I visited Greubel Forsey’s new atelier recently, the finishing workshop was working on the parts for the new Invention Piece No 3 (that was shown at this year’s Basel Fair ahci.watchprosite.com Starting even from the main back plate to the watch, Greubel Forsey’s attention to detail in finishing is evident. Even though this part of the watch will remain hidden from view, the plate is designed and finished to an exacting standard throughout The decoration on any Greubel Forsey watch runs right the way through the piece, whether the surface is evident to the outside world or not.

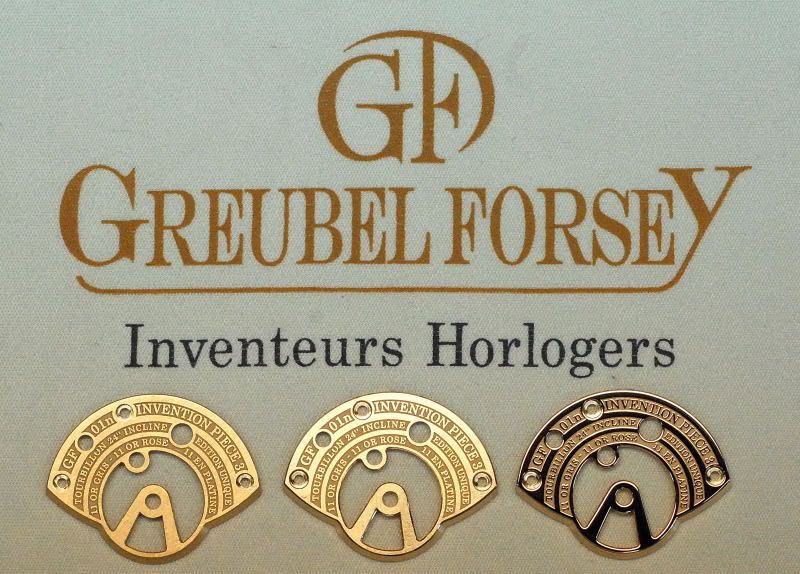

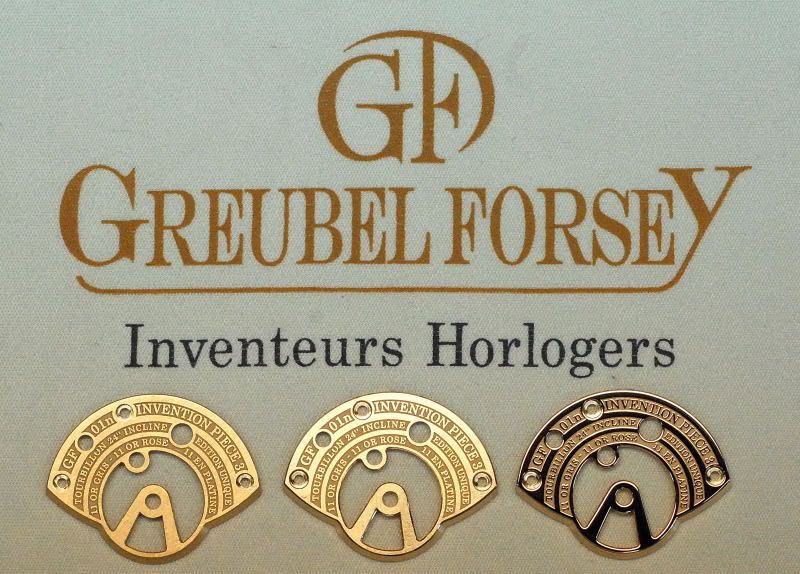

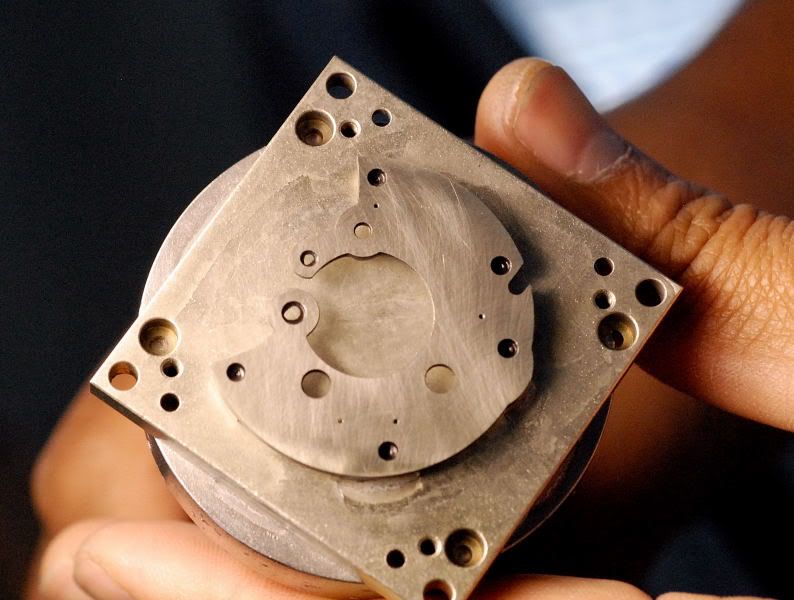

The attention to detail is evident in the back plate to the watch. The raw plates for the watch are made of nickel silver. This plate lies just under the Greubel Forsey ‘message’ plate; the message that the invention piece watch carries to its owner, that is a personal message from Robert and Stephen. Seems innocuous enough, but even here, there is a demanding finish to the plate that allows the message plate to sit atop, and so that the two pieces of metal fit flush with each other.

The plate starts off being machined with CNC. While the objective is always to end up with a smooth plate from the CNC machine, there is always the problem of a small metal bur or a slight inconsistency (steps) in the surface of the plate. The sort of ‘steps’ they are looking for here is approximately 2 microns in height. To spot such small errors, the raw piece is then bead blasted with glass beads to check for defects. The difference that is Greubel Forsey is that this is not the industrial type of blasting that is undertaken to remove defects and to promote the final finish; this is a blasting that will show defects, and if the defects are found, the plate is rejected. The finish that is left on the plates (providing they are not rejected) is a smooth surface finish. Hand perlage polishing is then applied to ensure that the surface is an exacting ‘mate’ to the adjacent surface and to culminate the matt blasting finish.

However, the thought and care on the manufacture and finish of the plate is especially apparent when you look at the smallest of details. For example, on the curved edges of the plate, the straight line grain finish can only be achieved by hand. Other companies (particularly on edges that will not be seen) will finish using micro motor and stone. The Greubel Forsey approach is hand finishing using a ‘buff’ abrasive stick. The difference lies in the straight parallel line finish from the use of the stick; the motor finish is less precise and will result in ‘waves’ that appear on the surface of the metal. The hand finish using the buff stick has a different aspect and finish. The counter intuitive thinking is that the finish that looks like it was done so by machine, is actually hand finished, and vice versa.

The finishing on the plate is even more remarkable when the perlage on the top surface is examined in a little more detail. It hardly needs stating that the perlage is undertaken by hand, but the important detail lies in the pattern. Closer inspection of the plate, and the free-hand spacing of the perlage surface, shows that inside the smaller perlage pattern lies a small ridge to the hole. The ridge is there for a purpose. The ridge provides the alignment for the top plate (the one with the message engraved upon it) to sit perfectly onto the plate below. The holes are there to hold the jewels and chaton. This provides a better aesthetic look as the plates containing the message are aesthetic and decorative and so does not play a structural role with the movement.

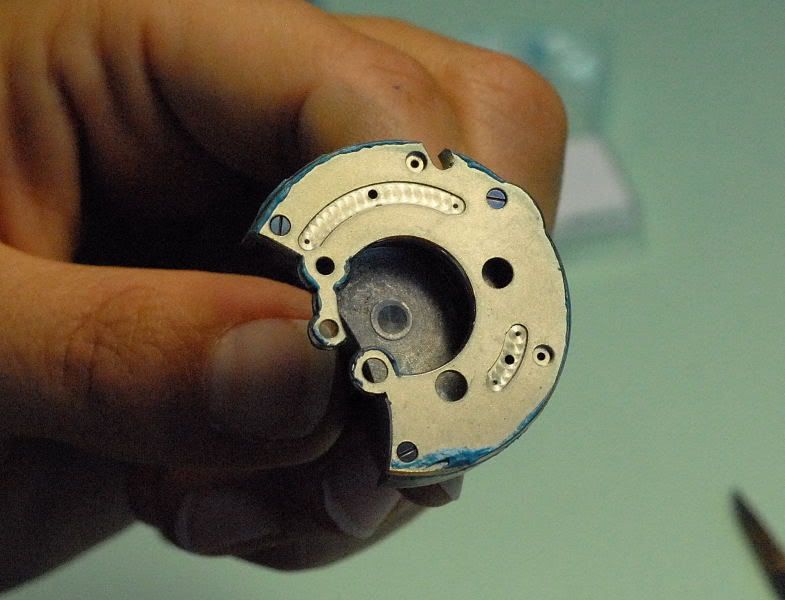

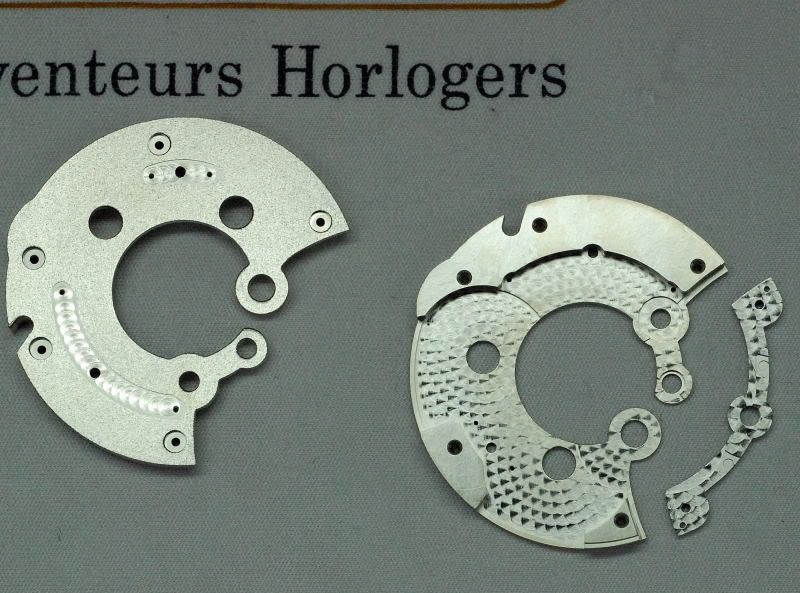

The same attention to detail is paid to the other hundreds of parts that make up a Greubel Forsey watch. The lower bridge to the Invention Piece No 3 illustrates the time and care taken in finishing both the surfaces that are visible, and those that are not:

The progression from the raw bridge, to the finished bridge is approximately 30 hours of polishing and anglage; even on the inside surfaces. Looking at the plates at different stages of finish, it is possible to see how the small changes to the surface and edges occur to result in the final plate that will be screwed onto the top of the nickel silver plate shown above.

Finishing is not just simply polishing every surface a lot and putting the watch together. The use of different finishing techniques give an aesthetic to the watch, and the extra effort and time taken to finish the watch on every surface provides a harmony that goes beyond just what is seen by the owner. Think of it this way, in the same way that car engines are still hand finished to get extra performance (although a number of the moving parts cannot be seen by the driver), that finish still radiates in the performance and feel of the car. It is something intangible to the eye, and yet felt through touch. There is an intrinsic value in hand finishing that pervades the watch.

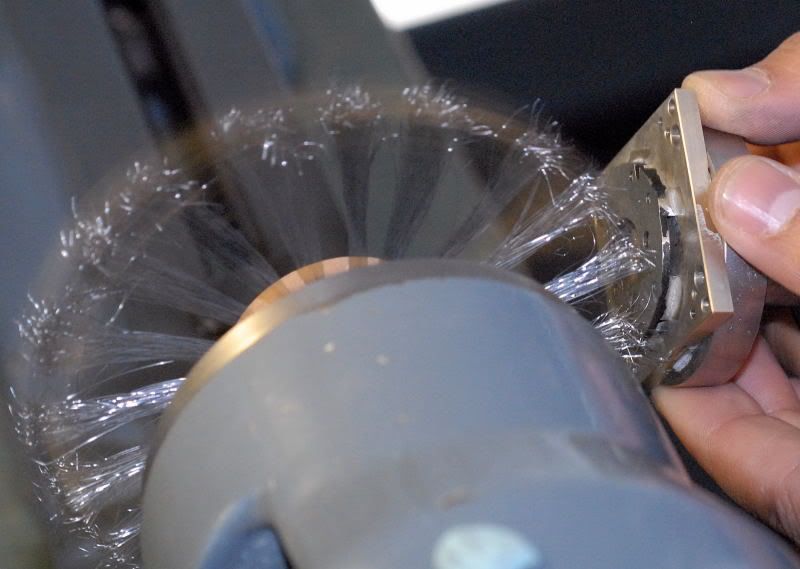

Finishing at Greubel Forsey applies a number of different techniques to different surfaces. Rather than use Geneva stripes, Greubel Forsey use a frosted finish on the plates. This is achieved by taking the nickel-silver plate metal and beating it with an electric powered metal brush. Once again, this cannot be undertaken in a simple mechanical way, there is a skill required in terms of the pressure to be applied to the plate from the brush.

Once again, the small details show through. On this example (the back plate to the 24 second incline) the location of the (gold) name plates are protected with small ‘fillers’ that are then removed after the brushing (leaving a perlaged intent). All angles are then polished by hand so that the finished effect is stunning. The frosted surface of the watch is juxtaposed with the polished and beveled edges.

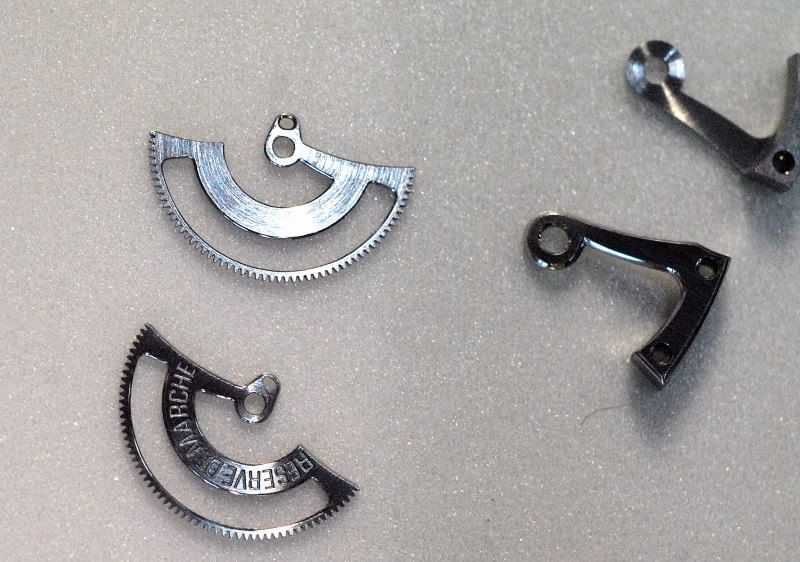

Every detail of a Greubel Forsey watch receives this attention to finishing. The finishing, while a fundamental element of the watch, is not so much an aim in itself, it is also to demonstrate and keep traditional watchmaking finishing alive and well. Every component, however small, is finished to the same exacting standard. Below, a series of before and after pieces from the 30 degree Double Tourbillon, and from the Technique:

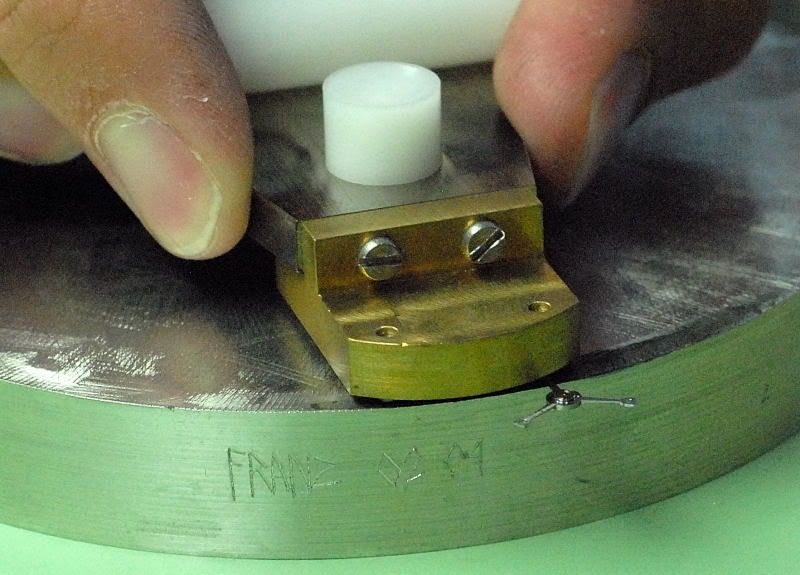

For example, the upper part of the tourbillon cage for the 30 degree Double Tourbillon is ‘black polished’ on four separate flat surfaces. The upper arms of the cage are at a slight angle and hence, to preserve the angle, to preserve the shape of each arm of the cage, a delicate hand polishing is undertaken. The cage part is held in a special vice, and then polished against the surface. Each time, the results are examined under an optical microscope to ensure the finish is perfect.

Overall, the types of finishing are combined to give the watch detail that is a hand worked effect. The invention pieces are not only to show case Greubel Forsey’s horological inventions, but also finishing and the way the application of different finished surfaces using the same metal can provide a different perspective, a surface where the owner can continue to appreciate the watch over time.

While the Greubel Forsey philosophy and the watches they manufacture are firmly aimed at the future; the research and development of accurate watches. The finishing and methods find their roots in the past. The same care and attention that was lavished on the most complicated hand finished pieces of yesteryear is still apparent on the Greubel Forsey watches. It is in the small details that a hand made watch looks almost machine made. But what separates the Greubel Forsey watches from others is the use of finishing as an aspect of the watch, rather than just a part of the watch. The new ‘Technique’ series, seen on Robert’s wrist that morning is both a show case for the innovations, but also for finishing at every level of the component parts that comprise a Greubel Forsey watch.

While finishing a watch to Greubel Forsey’s exacting standards takes time, it is ironic to think that in no time at all (just five years) the firm has grown from a hand full of employees to about 63 at the current time. In awarding Greubel Forsey the 2009 Prix Gaïa at the MIH. Award for 'Esprit d'entreprise', Robert and Stephen have demonstrated that the watch collectors out there appreciate and understand inventions and finishing can make an important difference in quality to the watch. My congratulations to both men and to all at Greubel Forsey for this well deserved award.

Andrew H

This message has been edited by AnthonyTsai on 2009-10-12 20:06:50 This message has been edited by AnthonyTsai on 2009-10-18 08:45:39

Taking Time: Finishing at Greubel-Forsey.

Thanks Andrew...

Thank you Andrew

Great insights. Thanks.

Thanks for the report Andrew

Beautiful technique that enhances the watch

Thanks for the tour.

very nice, thanks for the article

Very informative article, and I also must ask...

Excellent report!

Excellent report, thanks

Thanks for Excellent Report.

Thank you Andrew for this extremely detailed and informative report.

Stunning craftmanship and what eye for detail............

It's the time and care put into the details that makes a

equally true

Astounding craftsmanship...

awesome stuff

+1

Late again