Ondrej Berkus

254

Here's what i could think off

that might be interesting to see.

Also, thank you Mr.Corson for fixing the video. Much obliged

Here's my lathe i was talking about. Pretty standard lathe with two modifications - dividing plate (can be seen leftmost of the picture) and a plate to mount a milling head on (on the support),

this milling head,which is detachable from its base, including the leg. That allows me to cut my own gears. The machines i use are a bit larger than a usual watchmaker's lathe, but the benefit of that can be seen on the finish of parts. When you let a carbide cutter run into steel at 5000 RPM, you get virtually no chatter marks and very little polishing left to do. Which is a good thing, regarding the geometry of the teeth.

There are also drills (steel and carbide alike), files and a minion in this picture

My whole shop. Didn't mean to brag that i have a bike, i was a bit too lazy to move it out of the shot. On the left, there is my 'assembly' table. And there is no CNC anywhere... i'm pretty proud of that

My gear cutting tools - to clarify, i don't cut the pinions dead hard, but in a final, heat treated state. I have my round steel professionally heat treated (at a company that used to treat my knife blades back when i was making knives ) to a proper spring hardness for that steel. I actually do the same with flat steel for springs and other stuff (which can then be easily milled with carbide endmills and drills). With the steel pre-heat-treated, i can turn everything to size, cut the teeth, polish pivots and burnish them in one chucking, theoretically eliminating any errors from re-chucking.

No, that's not true, i burnish the other pivot after parting off. Other than that, yeah, that sounds about right

So, the tools - little rectangles cut out of carbide that have the tooth gap at both ends, relieved to be able to cut the material without galling.

There is also the mount for them, which is pretty self explanatory i think

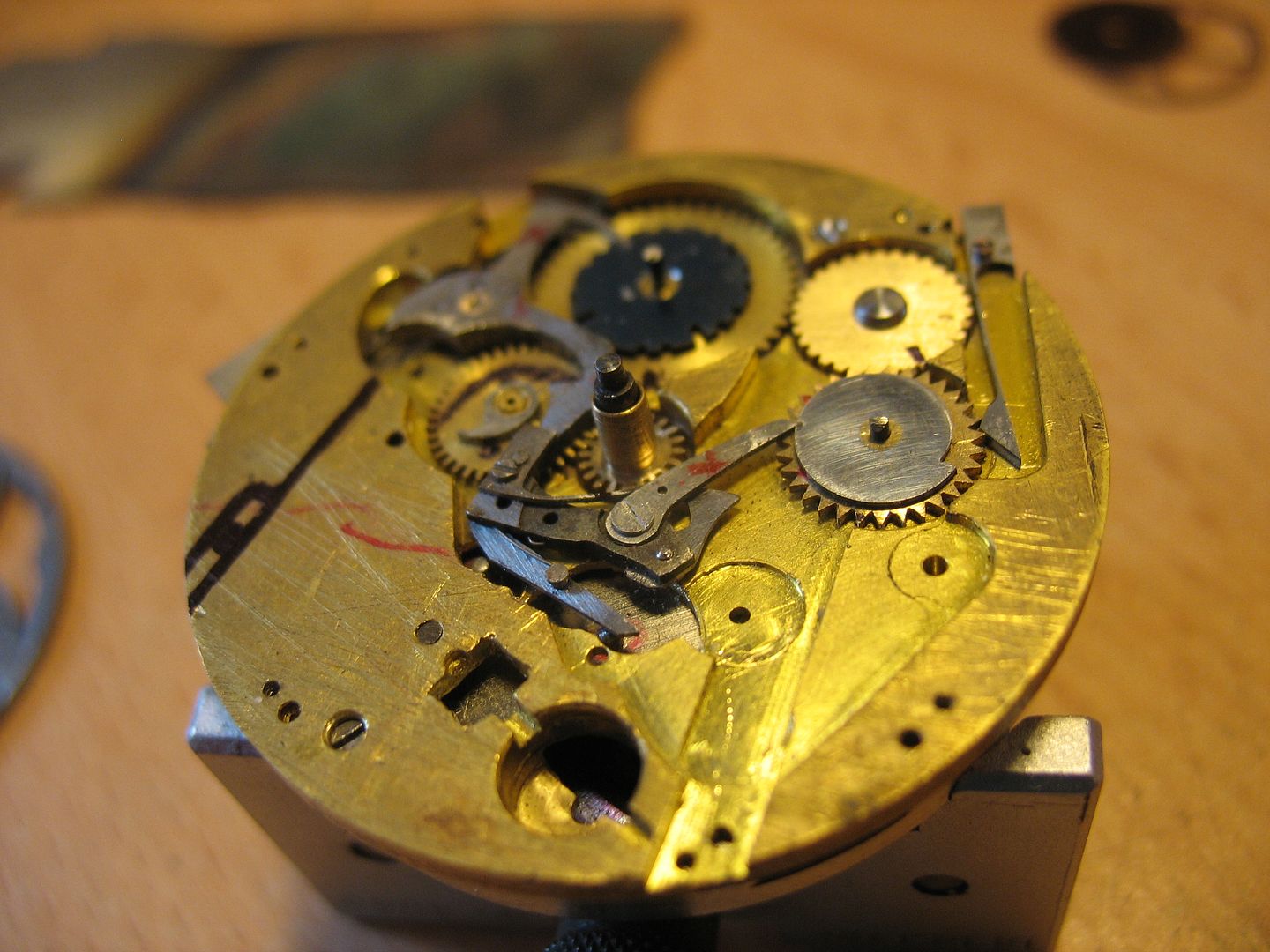

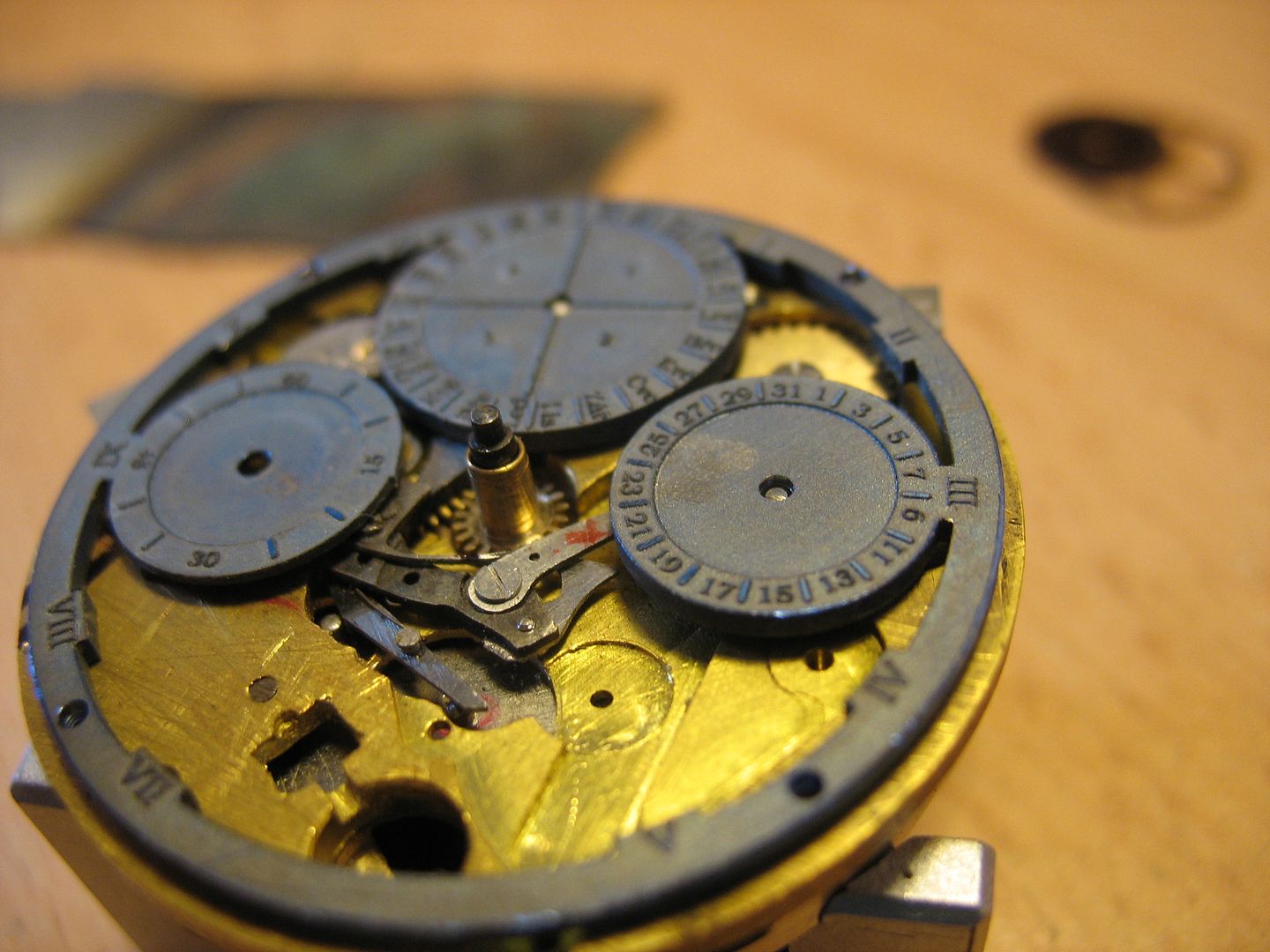

The parts for the tourbillon, shown separately - wheel blanks ( i have cut two of each - 80&75 teeth, to have something to destroy,if it comes to that), screws, bridges, barrel arbor blank, barrel.

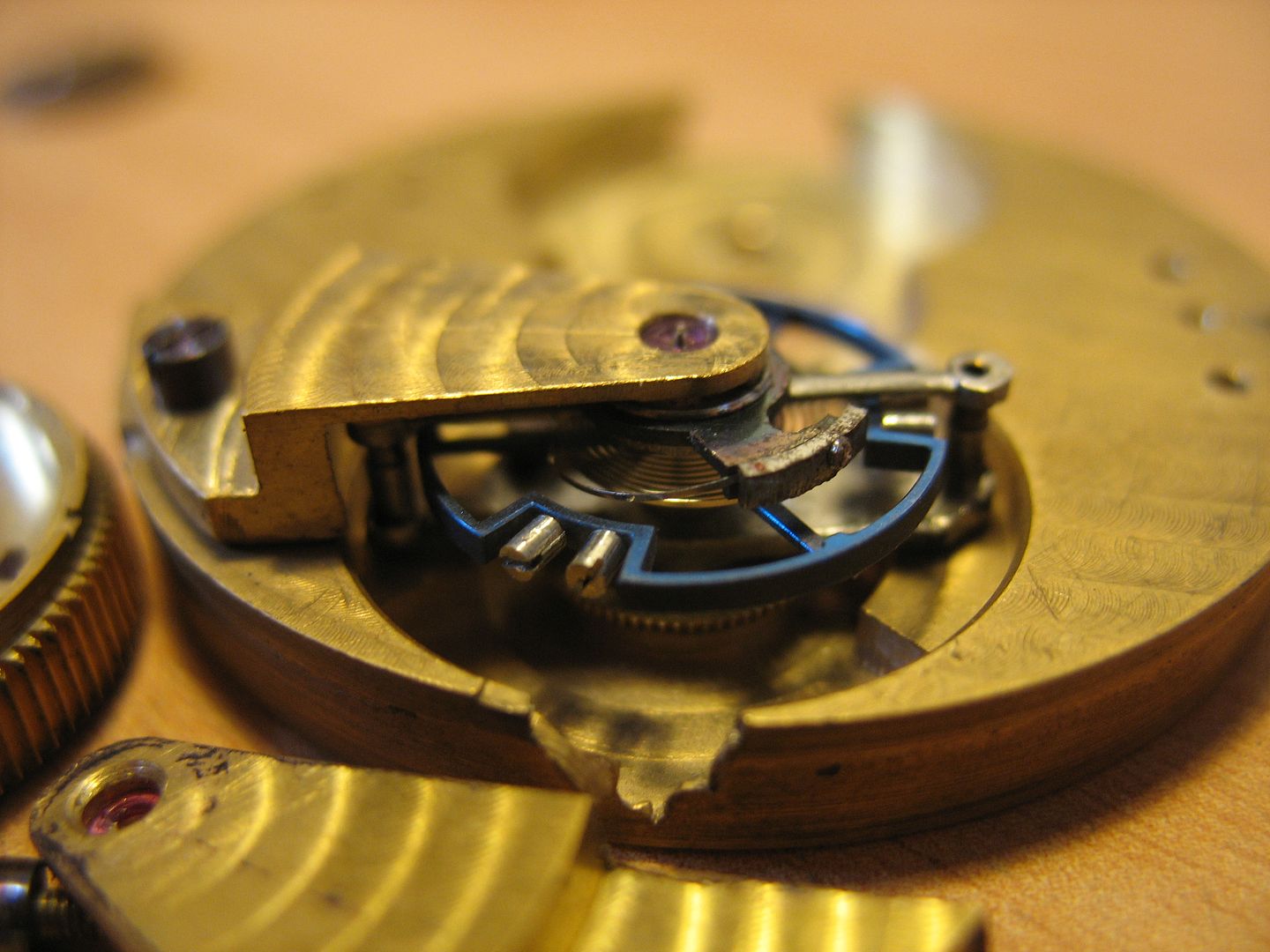

tourbillon close up

other side, do you see the DLC coated escape wheel? No oil needed

Another little thing i've been working on actually got to work properly today

i have to admit, to be absolutely clear, i'm making this for a friend of mine. He challenged me after discussing the possibility of this being made by hand  The tourbillon will be staying with me though

The tourbillon will be staying with me though

The making process is really something that i like, enjoy and can get really carried away with. But, as any obsessive mind, i am already thinking of things i can do better, things i will do better on the next one. It's kind of a neverending story, really...

Thank you for looking,

Ondrej

Well, i'm pretty happy about how this turned out

Rough or Smooth

This looks excitingly promising!

You are right

You've done what 99.9% of us cannot do

Awesome work

[OT] finishing titanium

"Pretty happy" ... you master understatement...

Well,

Nice, very nice.

Here's what i could think off

A tourbillon ... and a perpetual calendar !!!!!!

Thank you,